By: Domenico Amodeo

Discovering Practical Solutions and Tax Incentives to Prepare for National Security Challenges

Summary

Bottom Line: This article proposes practical solutions and tax incentives to strengthen the industrial base for future national security challenges, drawing inspiration from Bill Knudsen’s strategic insights.

Key Points:

- Bill Knudsen’s influence on government decision-making and his success in generating demand and capacity for machine tool manufacturing during wartime serve as the foundation for the proposed solutions

- The article suggests three potential solutions: policies to overcome barriers to entry, modern collaborative and advisory mechanisms, and digital solutions for exploring defense industrial base integrated capabilities.

- It explores the idea of tax incentives, such as a depreciation reset policy, to stimulate small and medium-sized manufacturers to participate in a potential wartime economy.

In-Depth: For a deeper understanding of the proposed solutions and tax incentives, the article provides detailed insights and examples of how these measures can contribute to fortifying the industrial base for national security challenges.

Introduction

William Knudsen, a man of unique genius, was not just an engineer, auto executive, and three-star general but also a strategic thinker across business, leadership, and manufacturing. His ability to leverage relationships, build credibility quickly, and marshal diverse resources to create tangible results was unparalleled. Arthur Herman’s 2013 book Freedoms Forge beautifully narrates Bill Knudsen’s compelling life story. As America faces the threat of peer-on-peer conflict on a global scale sparked by the recent Russia-Ukrainian war, the ability of our industrial base to rise to the challenges is a genuine concern. In these times, it is not just enlightening but crucial to reflect on the solutions and insights of Bill Knudsen that can be adapted to the contemporary situation.

Knudsen’s influence on government decision-making was not just successful but also inspiring. His first success was arguing against any degree of central planning or nationalization of industry. The government would generate demand, and the industry giants and entrepreneurs would find a way to supply while creating jobs and profit. This was not just a strategy but a reflection of patriotism inspiring action and profit, unleashing innovation. Knudsen aimed to preserve a core tenant of American culture, and he and his colleagues demonstrated competence against government inexperience and faulty assumptions. Their technical competence and virtue preserved America’s business culture from the threat of government overreach during a crisis.

Knudsen’s second, less ideological impact, was his ability to generate demand and capacity for machine tool manufacturing before end-item demand. This practical approach accelerated the production of necessary war-related end items when demand exploded in 1941. In contrast, numerous advisory boards during the war proved inept at assisting the government in giving purpose to the latent industrial might. At their worst, these bodies misdirected and misguided policymakers and government planners on the requisite lead times to direct the industrial base to a war footing. Knudsen’s critical insight inspires us as we tackle positioning our modern economy to surge war production. This article puts forth three potential solutions to address discreet challenges in a surge, all inspired by Knudsen’s practical approach. First, policies to overcome barriers to entry. Second, modern collaborative and advisory mechanisms. Third, digital solutions for exploring defense industrial base integrated capabilities. These solutions are not just theoretical but practical and feasible, designed to ensure the smooth and efficient operation of the industrial base during times of national security crisis.

Tax Incentives to Promote the Surge

The idea of another war on the scale of WWII may seem outlandish to many Americans. The world has never been as prosperous, sophisticated, and economically connected. Many businesses may consider it unreasonable that any would-be adversary risks so much comfort for so little gain. Beyond the main armament contractors, few other companies are likely exploring potential niches for a wartime economy. However, small and medium manufacturers represent significant manufacturing capacity. The US government has a record of passing laws to stimulate segments of the economy deemed necessary for national security. Examples include the Jones Act, the Buy American Act, and the Cargo Preference Act. The government may consider similar laws targeting small and medium-sized manufacturers.

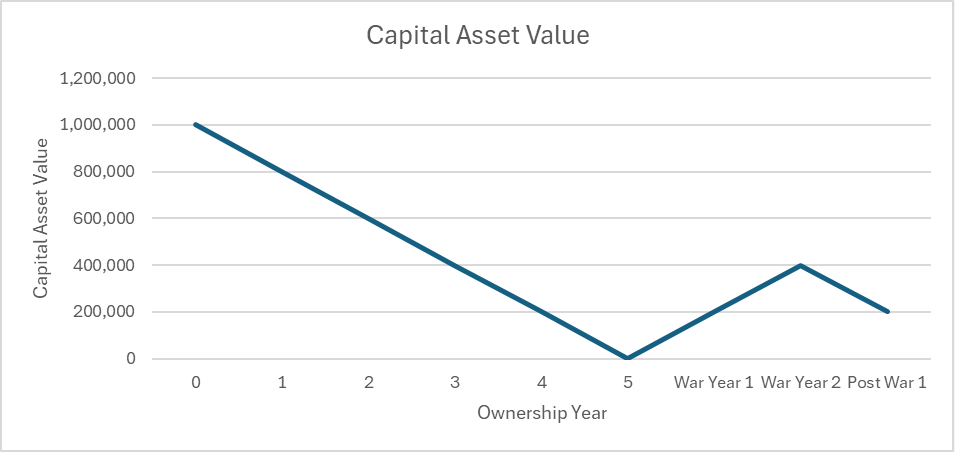

One policy incentive to consider is a depreciation reset policy. This policy would allow manufacturers to reset or buy back depreciation by participating in a war economy and provide them with a financial cushion and a strategic advantage. The depreciation reset of a capital asset occurs whenever the asset is used in military, wartime, or national security production. For example, imagine a $1M piece of equipment was fully depreciated over five years. The manufacturer uses this equipment in the sixth year to support national security requirements. At this point, the value would be added to the depreciated asset on a reverse depreciation schedule. Figure 1 depicts how the capital asset valuation would look to the manufacturer. This policy has two benefits. First, it allows the government to compensate manufacturers without additional cash requirements. Second, as reverse depreciation reduces taxable income in post-war years, this income can be used to re-invest and reset manufacturing lines.

This tax policy benefits participating manufacturers when war demands occur and underscores the crucial and irreplaceable role of small and medium-sized businesses in national security production. However, many manufacturers may see the probability of a war as low and thus be unwilling to participate in the program. For these manufacturers, the government may need to devise different incentives. One potential policy is for the US to establish standards for small and medium-sized businesses to participate in national security production. The government may sanction a private non-profit like the American National Standards Organization to develop standards and certify participants. The standards should represent the minimum threshold for participation in national security procurement processes and have low costs and administrative burdens. Compliant manufacturers should receive an annual tax rebate commensurate with their implied capacity. This tax rebate would incentivize investment and maintenance of latent capacity and recognize and appreciate their significant contribution to national security.

Combined, these policies incentivize small and medium manufacturers to position their operations to participate in a surge for national security purposes. However, in the spirit of Knudsen, these policies must be seen as something other than involving a high burden of compliance or intrusive government oversight. The industrial base hardly needs another burdensome and expensive barrier to entry like CMMC 2.0. Successful implementation requires a level of oversight between the government and the producers. One potential solution is the theoretical National Surge Board.

The National Surge Board

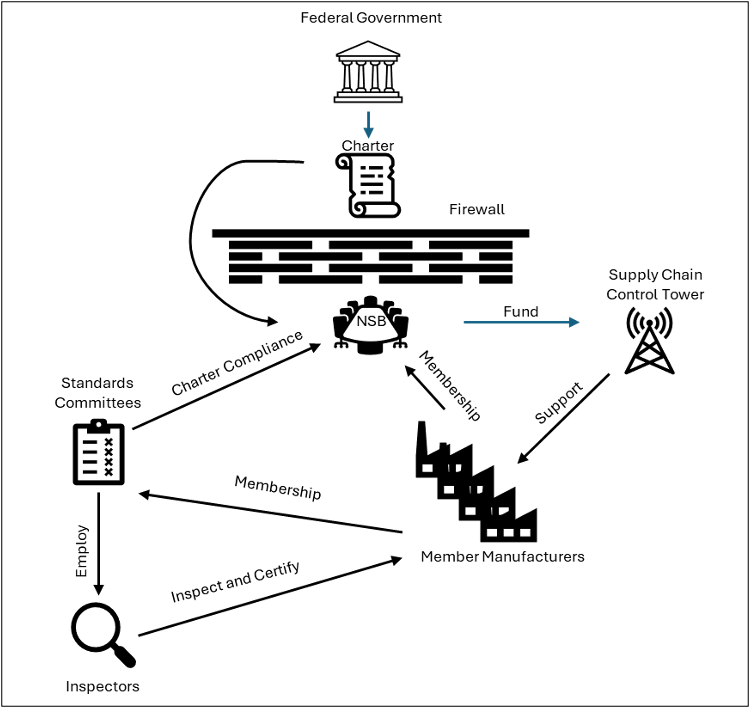

Like existing standards organizations, NSB will have industry and cross-functional committees. These committees are responsible for developing standards and the corresponding inspections and certification maintenance programs. Committee members will be peer-recognized engineering, production management, and supply chain experts. Once standards are developed, NSB member firms can review and comment on standards before voting to accept or reject them. Once standards are accepted, the NSB creates a certification program. Inspectors should be experts within the relevant fields and clear a threshold for impartiality to ensure inspected firms are not subject to corporate espionage or corruption.

Many small and medium firms need the funds or scale to protect their digital systems or monitor their supply chain risk. The NSB provides a shared service for cyber protection and supply chain risk monitoring for member firms. The NSB will set up a supply chain control center. The control center will implement supply chain monitoring software from specialized firms such as Exiger and Interos to constantly surveil the supply chains. The control tower will monitor news reports, social media, and trade news and develop sources to identify, validate, and assess risk. As risks are identified, the control tower will send custom daily reports to member firms. These reports will cover the risk to a specific firm’s supply chain. As the control tower identifies and reports on risk, it will also flag risks that result in non-compliance with standards such as the Trade Agreement Act. Firms will be given a designated amount of time to achieve compliance before losing their certification. However, the NSB will help firms de-risk their supply chain by validating new supply nodes against known threats. In this way, the NSB can help members re-comply faster and thus maintain capacity in the industrial base. Figure 2 shows a potential organizational structure for the NSB. Since the NSB is a member-governed organization, company expenditures, including the wages for board and committee members, should be compensated through tax rebates or credits.

The NSB is designed to support “surge manufacturers.” These small and medium operations may lack the resources, business cases, or knowledge of government procurement to become defense contractors. The NSB helps lower the barriers to entry. However, membership is not enough. Members must be capable of supporting a specific manufacturing need.

Preparing for a Wartime Pivot

Modern manufacturing continues to trend toward being automated and versatile. Robotic devices and production lines can quickly be programmed in days and weeks rather than months. Even non-robotic machines can be programmed to specifications, thus reducing the opportunity for human error. However, not all small and medium manufacturers heavily rely on automation. Manufacturers certified by the NSB and compensated by the government should have a validated capability matched to a defense requirement set. Given many defense requirements, matching requirements to capabilities may prove difficult. Here, we propose a two-part solution.

As part of the charter, the NSB will certify manufacturers based on high-level technical requirements defined by the government and large prime contractors. Three generic examples are.

- Precision Metal Plating: The Manufacturer must be able to provide precision metal plating on components ranging in size from a hand tool to a car door.

- Electric components/Cable: The manufacturer must be able to produce Ethylene Propylene Rubber cable conforming to industry standards.

- Engine components: The manufacturer must be able to produce engines, including pistons, gears, crankshafts, and piston rings, from composite metals

Traditional prime defense contractors and the government will retain the ability to run simulated manufacturing exercises at most once per year and require at most 100 person-hours on a given manufacturer. These exercises should be coordinated through the NSB and done on a digital application. They might proceed as follows: The prime contractor submits a requirement for a new component to an NSB member on a digital system. The component is non-standard but within the realm of the manufacturer’s capability. The manufacturer returns a technical artifact. This response details the timeline for turning over an existing production line, material and workforce requirements, and any gaps in machine tools, space, power, skills, or other resources that must be mitigated before production can start. The exercise system must be designed to 1) protect confidential or close-hold firm information, 2) serve as a pre-demand market and price research tool for the government or prime contractors, and 3) help the firm anticipate future needs and areas for process improvement. These exercises help the industry identify gaps and rehearse their processes and procedures for responding to defense surge demand.

The whole industrial base can better understand capacity and potential gaps by periodically leveraging digital technology to extend a tabletop exercise. Combined with supply chain risk monitoring, this process can uncover economic opportunities. Gaps and risks present a financial opportunity for entrepreneurs willing to start a business in the niche that either expands capacity or helps de-risk the network. As always, participation in the exercise should be voluntary, compensated, have a low burden, and have transparent outcomes.

Conclusion

Transitioning our economy to a wartime footing has challenges different from those 80 years ago. On the one hand, supply chains and production are more complex and global. Systems are more sophisticated and require greater precision. On the other hand, information technology allows for incredible integration and coordination, unfathomable in the past. Despite these differences, fundamental attributes of American society remain unchanged. Our government requires the people’s consent to go to war. This consent goes beyond what is expressed through the legislative bodies; it also includes the willingness of our citizens to participate in the effort. Firms must believe in the cause and trust the government before shifting production. The proposed policies address this concern by providing a self-regulating body of participants with incentives and mechanisms to participate. These policies also create a protective wall of checks and balances to protect private interests from an intrusive government. While the American government can and does own and operate some limited defense manufacturing operations, it cannot forcibly nationalize or direct economic activity. The financial policies proposed here offer a potential solution for incentivizing companies to lean into the surge by providing compensation and rail guards on the loss of capital investment before demand materialization.

About the Author

Domenico Amodeo holds a PhD in Systems Engineering and is an officer in the U.S. Army Reserve, where he commands a transportation battalion, with previous service in Iraq. He is currently a consultant for Accenture.